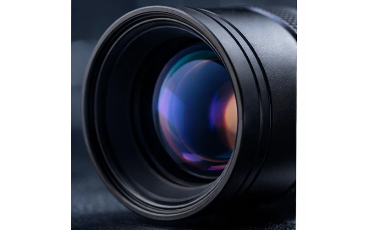

Visible vs. Infrared Optics: What Changes in Lens Design and Manufacturing (SWIR & LWIR)

Jul 23, 2025

Visible vs. Infrared Optics: What Changes in Lens Design and Manufacturing (SWIR & LWIR)

Infrared optics bring a different set of constraints compared to visible imaging. The wavelength band, material selection, thermal behavior, and coating requirements often redefine both design choices and manufacturing control points. Below is a practical overview for SWIR and LWIR projects.

1) Materials and transmission

Visible optics commonly use optical glass families, while IR optics often require specialized materials to achieve transmission in SWIR or LWIR. Material choice influences weight, cost, manufacturability, and achievable surface performance.

2) Coatings are band-specific

Coatings must be specified for the operating band and angle. An AR coating optimized for visible wavelengths will not deliver the same effect in IR. For IR projects, always define band, AOI, and (if relevant) polarization and environment.

3) Thermal behavior matters (athermal considerations)

Temperature changes can shift focus and image performance. Many IR systems require thermal stability considerations, which affects mechanical interfaces, assembly tolerance strategy, and validation during ramp-up. Clear operating temperature assumptions help prevent integration surprises.

4) Tolerances and assembly strategy

In imaging lenses, not every tolerance carries equal optical impact. A practical approach prioritizes the features that most affect performance and relaxes non-critical items to improve yield and cost. Sharing the system context (sensor size, FOV, integration constraints) enables better DFM decisions.

5) Validation from sample to production

For IR lenses, it is common to validate not only geometry but also real imaging performance under intended conditions. A pilot build is often the most efficient step to confirm stability before scaling to volume.

What to send for an IR lens inquiry

Band (SWIR or LWIR), wavelength range, and application scenario

Sensor format, target FOV, and key performance priorities

Mechanical interface constraints and operating temperature assumptions

Target quantities and timeline (prototype / pilot / volume)

Planning an IR project? Share your band, system constraints, and timeline. We can support DFM review, prototyping, and production coordination with a practical, scalable route.

Network Supported

Network Supported